Is Bronze-Cut Pasta Really All That Different From Modern Pasta?

There is pasta, and then there is pasta. Understanding this difference is more obvious in some circumstances than others. An obvious example: Chef Boyardee vs. homemade ravioli. Less obvious: the difference between bronze-cut and industrial boxed pasta. Of course, any Italian nonna worth her parmesan could tell you the difference immediately, but for the everyday consumer, the differences may not be as clear.

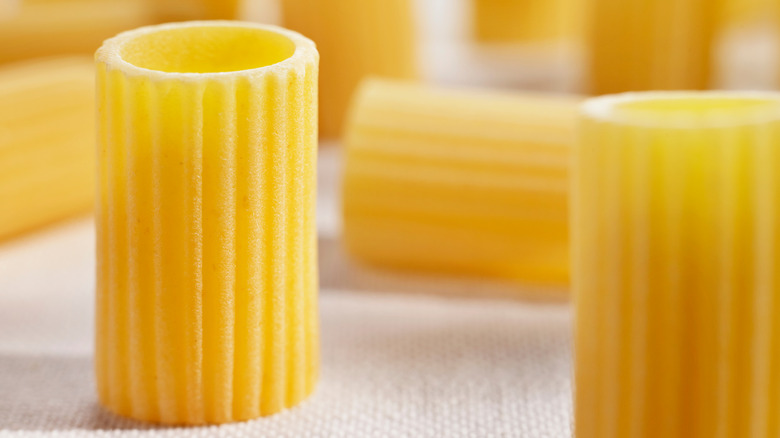

The pasta most of us are used to — the stuff that comes to us in boxes or bags — is what the Italians call pasta secca, dried pasta. This is in contrast to pasta fresca, which is fresh pasta. There is a place for both in Italian cuisine, but there is no doubt that the dried variety has a longer shelf life and is more widely available (via Italian Made). During the early days of industrially produced pasta, the various profiles, be they spaghetti or rigatoni, would be cut using something called a die. This metal plate would give the pasta its shape as the dough passed through it. These dies were typically bronze cast, but a cheaper metal with a Teflon coat is now what is most widely used, according to Patagonia Provisions). These newer dies caused the pasta to take on different characteristics, which relegated bronze-cut pasta to the artisanal market.

Of sauce, structure, and science

Though more and more manufacturers are developing lines of bronze-cut pasta, harkening back to the early days of manufacturing, the vast majority of commercially produced pasta still uses Teflon dies. But what's the big difference?

According to The Takeout, pasta that's passed through bronze-cast dies has a much rougher texture than those passed through Teflon. The advantage of a rougher texture on your pasta means that whatever you decide to top it with, be it a cheese or tomato sauce, will more readily stick to the pores in the pasta the bronze die creates. Scientists even believe that the rough cut texture allows the pasta starches to infuse better with the sauce.

Though bronze-cut pasta used to be relegated to the artisanal market, well-known pasta makers like Barilla have gotten into the bronze-cut game. Barilla's goal, according to Forbes, is to offer the home chef the ability to spruce up their home-cooked pasta with the type of cut professional chefs prefer. The company is using a newly developed die of bronze with micro-engraving for the best possible "rough cut." Though there's the obvious financial incentive, as The Atlantic points out, artisinal pasta can run three to four times higher than pasta secca. But if more manufacturers follow suit, we could be in the midst of a pasta revolution. And who, honestly, doesn't want better pasta?