12 Facts About Draft Beer You Wish You Knew Sooner

We may receive a commission on purchases made from links.

I'll be the first to admit that, on the surface, draft beer doesn't seem all that interesting. It's beer drawn directly from a keg, through a beer line, out of a tap, and into a glass. However, the truth is that draft beer is pretty fascinating.

My first exposure to the nitty gritty details of draft beer was over a decade ago when I was employed by the Dutch beer giant, Heineken. As a Brand Development Executive, I traveled the south of England, troubleshooting draft beer systems, monitoring beer quality, and convincing publicans to buy our brands. While the job wasn't particularly glamorous, I learned a huge amount about draft beer and was blown away by the science and stories behind the stuff. This knowledge served me extremely well when I realized I preferred working on the other side of the bar. I've probably spent more hours in beer cellars than some folks have spent in bars.

As it turns out, there's a huge benefit to knowing more about draft beer — you'll end up enjoying beer more than ever. If you run a bar or restaurant, draft beer knowledge will keep your beer tasting great and your customers happy, and it'll save you money in the long run. As a consumer, you'll gain the ability to know when to skip bad beer and how to identify the best brews. Plus, if you're anything like me, you might just enjoy pestering your mates down at the pub with nerdy beer facts.

Draft beer is older than you think

Nowadays, it's pretty common knowledge that beer is old. Really, really old. There's evidence that the laborers who built the Egyptian pyramids were paid in beer, and we've discovered beer recipes recorded on ancient Mesopotamian tablets. While these civilizations certainly didn't have draft beer, it's still been around longer than most of us realize.

Medieval European monks likely stored their beer in wooden kegs, a sturdy upgrade compared to the ceramic vessels of ancient times. Whether this counts as "draft beer" depends on your definition, as these monks didn't have a specific system for drawing the beer from the barrels. The first recorded mention of a mechanical draft system dates back to the late 17th century. Not long after the Great Fire of London, a man named John Lofting registered a patent for an early fire engine. Likely based on the same pump system, Lofting also marketed an engine for the "starting of beer and other liquors. Little is known about Lofting's engine, and it wasn't until 1785 that Joseph Bramah patented the hand-pull beer engine, a system still used for cask ale in many traditional British pubs. The rest, as they say, is history. By the early 20th century, pressurized, carbonated kegs started becoming commonplace, influencing the modern draft systems you see today.

The term draft beer originates from Old English

I've always found the etymology of English words incredibly interesting. All modern languages are derived from others, but few have seen as much outside influence as English. Interestingly, the term "draft" has roots in the heavily Germanic-inspired Old English.

In Old English, a language used on the British Isles between the 5th and 7th centuries, the word "dragan" meant to carry or pull. Over time, dragan evolved into words like "drag," "draw," and "draught." Countries like the UK, Ireland, and Australia still use the latter spelling, while "draft" became the Americanized version of the word. Draft horses were used to pull carts. An architect drafts building plans. Sports players are still drafted into teams from a talent pool, and a country's citizens might be drafted into its military.

In relation to beer, liquid is being pulled or drawn from the barrel to the faucet, so it makes sense that the term has stuck around. Confusingly, occasionally you might see the terms "draft" or "draught" on a bottle or can of mass-produced beer. In these cases, it's typically a marketing ploy by the brewer to imply the beer within is of draft quality.

38 degrees Fahrenheit is the sweet spot for draft beer

Everyone likes a refreshingly cold beer, but the relationship between draft beer and temperature is more important than you might think. If draft beer gets too warm, it can hurt the quality of the beer and make it harder to serve.

At higher temperatures, the rate of oxidation inside the keg increases which can lead to off flavors. Additionally, although most draft beer is stored in sealed, pressurized kegs, it's typically not pasteurized. This means bacteria can develop or fermentation can restart if the beer isn't kept cold enough. As a result, beer kegs are refrigerated during transit from the brewery to their final destination.

Most brewers adhere to what's called the 3-30-300 rule. Essentially, this rule dictates that a keg of your average draft beer will degrade at the same rate over three days at 90 degrees Fahrenheit as it would over thirty days at room temperature — roughly 72 degrees Fahrenheit. However, that same keg will last 300 days when kept at 38 degrees Fahrenheit, making it the sweet spot that brewers aim for. Plus, if beer gets too warm, the CO2 in the liquid breaks out of suspension. If you try pouring a pint, you'll end up with a glass of foam which is a waste of good beer. Although some ales and higher-strength beers are served at up to 55 degrees Fahrenheit, most lagers are still poured at 38 degrees.

The way you pour draft beer has a huge impact on quality

As I mentioned earlier, a large part of my role at Heineken centered around monitoring draft beer quality. When a brewer produces bottled or canned beer, there's a pretty good chance it'll taste how it's supposed to once a consumer cracks one open. With draft beer, more factors are out of the brewer's control, and the way it's poured was always my biggest focus.

There's a lot more to pouring the perfect pint than simply opening the faucet and filling the glass. The pressure in the beer lines needs to be right. The glass should be "beer clean." The glass needs to be held at the correct height and angle while pouring, and the faucet should never enter the liquid. I've covered all of these aspects previously in my comprehensive guide to pouring draft beer, as well as the reasons why following these rules saves money and leads to a better-tasting pint. At Heineken, I'd prove my point to bar owners by conducting a blind taste test. I'd serve three beers from the same tap — one poured properly, the others using incorrect techniques. They picked the perfect pint every single time.

Draft beer's head has an important function

The iconic foamy head of a draft beer is often written off as a simple byproduct of pouring but it's much, much more than that. It serves a crucial role in preserving the quality of draft beer and ultimately enhances the drinking experience.

For starters, the head is more than just extra bubbly beer, otherwise, a glass of soda would have one too. The proteins from the beer's hops and barley are highly hydrophobic, so they coat the rising bubbles of CO2 gas and rise to the top of the glass, clinging together to form a tight, foamy layer. Interestingly, this has some beneficial side effects. The head acts as a sort of protective barrier, slowing the release of CO2 and keeping out oxygen. This prevents the beer from going flat too quickly while also reducing the rate of oxidation which can cause off flavors to develop.

A foamy head also contains volatile compounds that provide the beer's aroma, so a longer-lasting head means you get to appreciate more flavors with every sip. This is why some beers, such as German wheat beers and Belgian ales, are typically served with a larger-than-usual head. It's also worth knowing that the head of a beer is still beer, so you're not being cheated if you get a pint with a hefty head on it.

You can tell the quality of a draft beer just by looking at it

While draft beer is typically superior to bottles or cans — we'll look at why that is a bit later — that only applies when it's served correctly. It can be hard to trust the quality of draft beer at an unfamiliar bar; however, some telltale signs might help if you know what to look for.

Clean glassware is a must for a perfect pint, and there are some giveaways that a bar's standards may not be up to scratch. If you see bubbles clinging to the sides of the glass, that means they're clinging to something that shouldn't be in there. Even clean glassware collects dust particles, which is why bars that are serious about their draft beer typically rinse their glassware before pouring. Fatty compounds called lipids will also produce this effect and can prevent the beer's head from forming properly.

If the foam dissipates quickly, something we call poor head retention, it can also be a sign of a dirty glass. That said, a lack of head isn't always a sign of bad draft beer. Stronger or non-carbonated beers typically struggle to form a head. While you should expect good head retention on a regular-strength lager, it's normal for boozy IPAs or cask ales to be served with less foam.

FOB detectors save beer and money

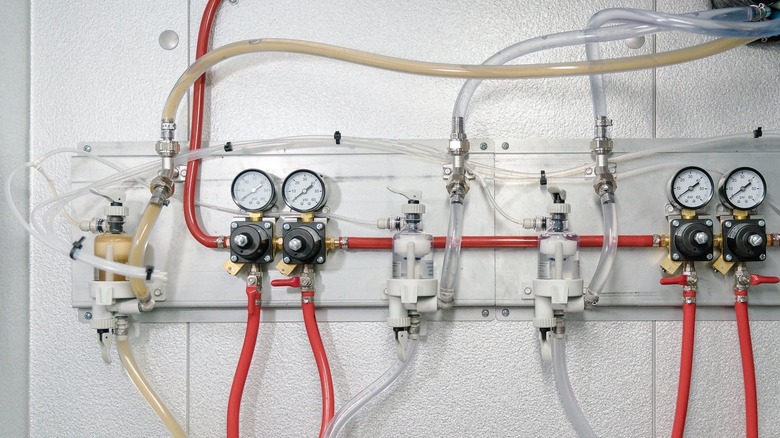

Draft beer systems have come a long way since John Lofting's beer engine. They've been adapted over the centuries to accommodate pressurized steel kegs, offer greater temperature control, and maintain the quality of the beer itself. Arguably one of the most significant additions to draft systems came about in the 1970s — the FOB detector.

FOB stands for "foam on beer" and it's a wastage nightmare for venues that serve draft beer. As I mentioned above, beer foam is still beer, so if the lines are spitting out unservable froth, that's money down the drain. Before FOB detectors, when a keg ran dry, air and gas would keep getting pulled through the beer lines. When the bartender changed the keg, the new beer would come out as foam unless they detached and purged the beer lines — a wasteful and time-consuming process.

FOB detectors are essentially a small, transparent chamber that's fixed onto the beer line for each keg. They contain a plastic ball that floats when beer is running through the line. When the beer runs out, the ball drops, blocking the line so air won't pass through it. Once a new keg is hooked up, a manual venting mechanism purges the gas from the chamber and pulls the new beer through. A second button or lever resets the floating ball, and you're ready to continue pouring.

Draft beer systems often require different types of gas

All beer is carbonated to some degree as a result of the fermentation process, although typically not as much as desired by the brewer. Some traditional beer styles get around this by conditioning the beer in kegs or bottles, which involves leaving live yeast in the barrel or bottle that continues to produce CO2. However, this isn't suitable for all beer styles, and different types of beer require different levels of carbonation.

In the early 20th century, it became more commonplace to use CO2 gas canisters to increase carbonation levels and force beer through the lines but this still didn't leave much room for adjustment. This problem was particularly irksome for Guinness whose world-famous stout requires less carbonation than your run-of-the-mill lagers. So, in 1955, the brewery hired a mathematician to solve the issue. The answer was to use a combination of CO2 and nitrogen, as the latter doesn't dissolve in liquid so it can be used to force beer through lines without over-carbonating it.

Nowadays, most draft systems use blended "beer gas." Lagers and ciders typically use gas with a 60:40 mix of CO2 and nitrogen, while real ales and stouts use a 30:70 blend. It's also becoming more common for venues to reserve a nitrogen-only line for serving stouts, as the smaller bubbles result in a much creamier mouthfeel.

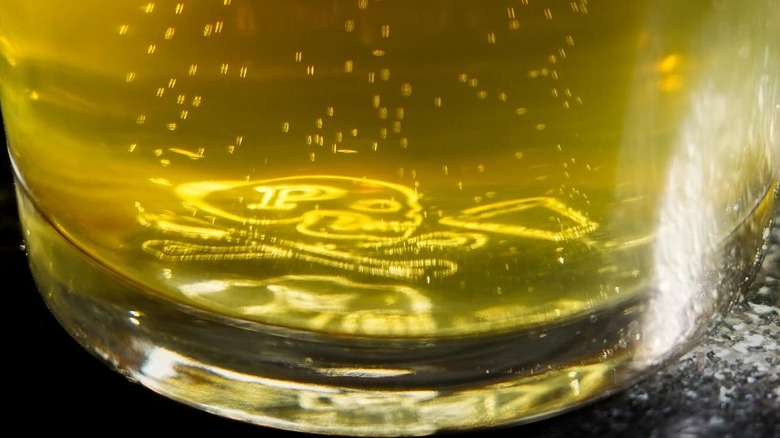

The markings at the base of a draft beer glass have a unique function

Next time you polish off a pint of draft beer, take a close look at the bottom of the glass. Almost every time, you'll see some sort of marking or indentation, whether it's a generic pattern or the logo of the beer brand. These markings are more than just a marketing gimmick and they have an important function.

The markings on the base of the glass are an intentional feature, intended to promote a process called nucleation. Nucleation is a bit tricky to explain completely in non-scientific terms but it essentially means that these deliberate imperfections attract and agitate the CO2 in the beer. The CO2 bubbles then rise upward in a steady stream, helping with head formation and retention. This also keeps the beer's aromas flowing at a consistent rate, contributes to a refreshingly effervescent mouthfeel, and provides a slight bitterness that balances the beer's sweeter flavors.

The method for marking a beer glass can also vary. Some markings are laser-etched into the glass, while others are made using tiny dots of enamel. If you need proof, simply pour a beer into a nucleated glass and a non-nucleated one. In the nucleated glass, you'll notice a clear stream of bubbles forming and rising from the center of the base, and the beer should retain its head longer than the beer in the non-nucleated vessel.

The right glass brings out the best in draft beer

It's no secret that beer glasses come in all shapes and sizes. There are countless styles to choose from, but the fact is some glasses are simply more suitable than others depending on the beer going into them. Even glass styles that date back centuries were typically adopted for good reason. Today, breweries that produce their own branded glassware often put plenty of resources into tailoring the design to best complement their product. Although using the wrong type of glass won't ruin a beer, it'll definitely detract from your drinking experience.

For example, pilsner glasses are tall and thin to highlight and maintain the lager's prominent carbonation. Wheat beer glasses are similar, but open up towards the top to allow space for the beer's incredibly aromatic, over-sized head. Bulbous glasses like snifters and tulips concentrate and amplify a beer's flavors. However, as a craft beer nerd, my favorite glass is the Teku. Created in 2006, the Teku glass is the ultimate beer-tasting vessel. The stem prevents the drinker from warming the beer with their hands, while the flared bowl is designed to enhance aromas and flavors while factoring in head retention.

Draft beer usually tastes better than bottled or canned beer

You'll often hear beer lovers claim that beer is better on draft and it's hard to disagree. Although draft beer requires a lot more care and attention to detail to serve it at its best, it is the better option if all of the right conditions are met.

The main reason draft beer tastes better is because it's fresher, meaning its flavors are brighter and more pronounced. Draft systems also allow a higher degree of control over things like temperature and carbonation. Additionally, although bottling and canning machines have improved over the years, they're likely to have more oxygen trapped in the beer than a pressurized keg.

Oxygen kills beer and results in stale or off-flavors, especially when it's stored at higher temperatures. Another beer-killer that many people overlook is light. While it's not an issue for canned beer, bottled beer can become light-struck which can result in a "skunky" taste. This is why most beer bottles are green or brown, as it prevents more — but not all — light from affecting the liquid inside.

Growlers let you enjoy draft-quality beer at home

For most of beer's history, the only way to enjoy quality draft beer was at a bar or restaurant. Although party kegs exist, they're usually only fresh for about 24 hours. That's not to say people didn't take draft beer home — as far back as the late 1800s, customers would take beer home in buckets which became known as growlers.

As you can imagine, draft beer doesn't really keep well in a bucket. Fortunately, in 1989, an enterprising brewer popularized a modern version — essentially a half-gallon glass jug. Nowadays, many breweries offer growlers for customers to take away fresh beer. Typically, you can obtain a growler in exchange for a cash deposit which the brewer or bar will refund if you decide to return it. Otherwise, you can top it up with your favorite beer on each visit.

While this type of growler is better than using a bucket, it's not a perfect system. However, growler technology has continued to flourish. You can now buy stainless steel growlers that you can pressurize with a CO2 cartridge, keeping your draft beer fresher for even longer. Crowlers, not to be confused with growlers, are another innovative method for letting consumers take draft beer home. These are aluminum cans that can be filled and sealed on-site with the help of a specialized machine. I've found crowler machines to be a bit of a headache to maintain and calibrate but the results are well worth it.