14 Facts You Didn't Know About Cheese Wheels

Cheese has been around for millennia — the earliest evidence points to pottery cheese strainers that were discovered in Poland dating back 7,500 years. The oldest intact cheese found was dated to be 3,200 years old, a testament to its enduring legacy, if not for its stinky aroma. From accidental curds to intentional crafting of countless cheese varieties, people have cherished cheese for generations, and history is full of fascinating anecdotes to prove it. Some even turned cheese into weapons during ancient religious festivals, like the Hittites roughly 4,000 years ago. Over the centuries, that cheesy passion evolved and today we have the pleasure of choosing from endless options.

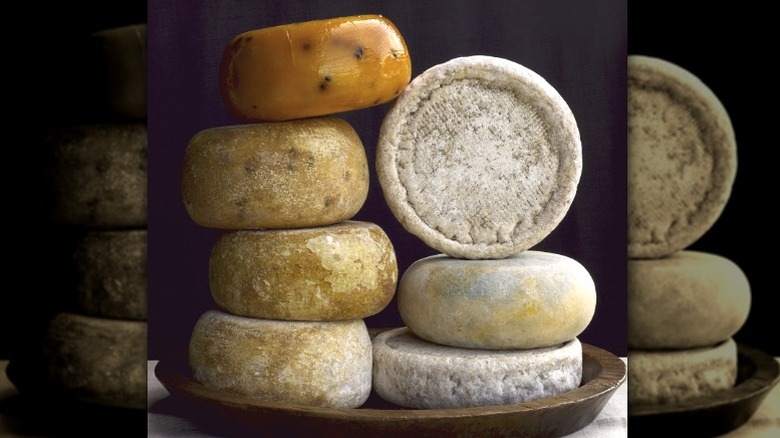

But how did the shape of the cheese wheel come about? And is there any purpose to its roundness? After all, when you're shopping at the store, you're likely to find blocks, slices, cubes, and wedges. To explore this, we consulted with Shannon Bonilla, American Cheese Society certified cheese professional and licensed Wisconsin cheesemaker, and owner David Major and manager Lindsey Datz of Vermont Shepherd for insights into the cheese wheel's origins, significance, and appeal.

Cheese was originally shaped into wheels for easier transportation

Innovative ideas are often prompted by practical matters. Part of the science behind cheese being crafted into a wheel shape had to do with simple necessity — milk was stored in round ceramic containers. Over time, this practical choice revealed other advantages: the round shape produced a sturdier cheese, and, specifically, allowed it to move easily. "Historically, cheese was shaped into large wheels to make transportation easier," Shannon Bonilla confirms, noting that "large cheese wheels could be easily rolled."

Though you typically see small wedges, blocks, slices, shreds, or cubes of cheese in the store, those portions come from a wheel of cheese. The size, shape, and type of wheel depend on the variety being crafted. This means cheese wheels range in size from small, family-size ones weighing about 1 to 2 pounds, like baby Gouda or mini-Cheddar, to much larger wheels that can weigh up to 85 or 100 pounds, such as Parmigiano Reggiano and Swiss. Wheels too heavy to carry became easy to roll wherever they needed to go.

Round cheese allows for less mold penetration

One of the many benefits of fermenting and storing cheese in a round shape is the absence of seams. David Major explains that the rounder the surface of an aging cheese, the less opportunity mold has to penetrate the surface and ruin the cheese. Shannon Bonilla elaborates, "Rectangular blocks have seams and corners where the microflora collect, creating the potential for cracks or splits." The round form, she notes, allows the microflora to distribute evenly across the cheese's surface.

This microflora plays a crucial role in developing the rind, which promotes a more uniform texture and flavor throughout the cheese wheel. "As the cheese ages," Bonilla continues, "the rind is used as protection from harmful bacteria and allows for moisture to slowly evaporate" This process creates aged cheeses, like Parmesan and Gouda. The more moisture that evaporates, the stronger the flavor becomes, she explains. Ensuring the microflora remains on the surface contributes to the specific type of cheese being made. The reason some cheeses — particularly the washed-rind ones — smell so bad is that the microflora is encouraged to grow and multiply on the surface, often with the aid of brining.

The round shape promotes even aging

To craft cheese into a high-quality, finished product, it needs to undergo effective aging. Each type of cheese requires a specific aging period, and if this process is disrupted, the final product can end up uneven or unbalanced. Shannon Bonilla explains that the wheel shape allows the cheese to age evenly, whether it's Gouda, Alpine, or Brie. Just as the round shape prevents mold from penetrating the cheese, it also ensures proper moisture distribution, keeping one part of the wheel from drying out more than another part.

In addition to even aging and moisture balance, Bonilla notes, the round shape creates ideal conditions for rind development. All of these traits, she says, contribute to the final taste and texture of the cheese. The size of the wheel varies, from small rounds to hefty ones, but the circular form keeps the aging consistent no matter the scale of the cheese. That trait is true for short-aged, soft cheeses, or those that mature for years. This sets the stage for developing each of their distinct flavors.

Some types of cheese rely on the round shape and rind for its flavor

There are some types of cheese that wouldn't be what they are without the round shape and accompanying rind. The way the round shape promotes even aging and balanced drying, the roundness contributes to the type of rind preferred to achieve different types of cheeses. These cheeses depend on their shape for the unique flavor and bite that define their end result. "Certain types of cheese, like Gouda, Alpine-style cheeses, and Brie," Shannon Bonilla explains, "are commonly made into wheels because their flavor, texture, and overall development depend on the rind."

There are four main types of cheese rinds, each delivering a distinct product. Originally, most aged cheeses were naturally rinded or wrapped in cheesecloth, David Major tells us. These days, rinds include bandaged-wrap (cloth), wax, natural bloom, brine wash, and air-dry varieties. Maintaining the wheel shape with each of these rind types ensures the crafting of high-quality cheese. Not all rinds are edible, but for those that are, they offer another layer of flavor and bite.

Most cheese wheels are artisanal

There's a difference between commercially-made and artisanal cheese, the latter referring to cheese crafted in small batches, typically by skilled professionals. Their method is more traditional and usually relies on locally sourced ingredients. David Major tells us, "In modern times, much cheese is aged vacuum-sealed in plastic." You see these blocks at your local grocery store's deli. "These cheeses are typically made in blocks," he explains, "because their aging involves no mold." Some popular brands of cheese that make cheddar, Monterey Jack, Colby, or processed cheese fit this description.

"In my experience," Lindsey Datz adds, "most artisanal cheeses that do a natural rind are round, while more commercially-made cheeses are in blocks." The round shape allows for a wider variety of styles when the humidity, salt, and microbial growth are adjusted evenly across the surface. Artisanal-style cheese is crafted with more attention and nuance to influence the outcome, whereas block cheeses skip those steps in favor of a uniform, controlled process. Datz says this is likely due to a simpler aging process when they're not using mold. Cheeses like Brie, Parmigiano Reggiano, and blue mold cheese are a result of this more complex aging process.

Small wheels produce fresher cheese

Cheese wheels are made in sizes ranging from small to large, anywhere from a couple of pounds to a couple hundred pounds. "There are two points in time that determine a cheese size." Lindsey Datz explains. "The first is the size of the cheese mold." Naturally, smaller molds produce smaller cheeses, she says, but how long you age your cheese also affects the final size of the wheel. David Major adds, "Smaller wheels age quicker as they age from the surface inward." He also notes that smaller wheels absorb salt faster. These factors allow the cheesemaker to produce fresh, salty cheeses like Chevre, Brie, or Queso Fresco.

Style and aging time are key factors in determining size and shape. Smaller wheels yield fresher cheese but since they ripen quickly, Shannon Bonilla explains, "any cheese that needs a long aging time needs to be larger." Small, fresh cheeses like Brie, she says, feature a higher surface area to volume ratio. This promotes faster moisture evaporation, which speeds up the aging process. The result is a soft-textured cheese with a delicate flavor.

Large wheels are designed for lengthy aging

Just as smaller wheels create fresh cheese, larger wheels produce aged cheese. Large wheels are designed for lengthy aging, Shannon Bonilla explains, so they can develop deep flavor over time. They lose moisture gradually, she says, so the end result is denser with more complex flavors. "This is why younger cheeses are creamier than aged cheeses," Bonilla notes, "and why aged cheeses can have a stronger flavor and develop crystals." The round shape allows cheesemakers to regulate the aging process, which directly impacts flavor and texture.

"Cheese matures from the outside in," David Major adds. "The bigger wheels take longer to develop flavor and longer to dry." For this reason, Bonilla says, the size of the wheel is chosen intentionally in order to match the ripening needs of the desired cheese style. This ensures the best possible texture and taste for the cheese being crafted. Larger wheels also give artisans the flexbility to experiment with humidity and rind development, tailoring the final product even more.

The rind directly affects aging, flavor, and texture

"The rind," Shannon Bonilla tells us, "plays a crucial role in a cheese wheel's aging process, flavor, and texture." The rind forms in a way that depends on the cheese style. There are four main types of cheese rinds: inedible, bloomy, washed, and natural. Each creates a distinct style of cheese. "Some cheeses," Bonilla says, "such as Roelli Cheese Haus Red Rock, develop a natural rind as they age." This is shaped by the microflora in their environment. Natural rinds create firmer cheeses because dry air during aging pulls moisture out. The salt in the cheese pushes more moisture to the surface, leaving behind a tough exterior after evaporation. The outside is technically edible, but can be tough to chew, though leftover rinds can be added to soups or sauces, where they soften and add flavor.

"Others, like Uplands Cheese Pleasant Ridge Reserve," Bonilla explains further, "are washed to encourage specific bacterial growth, creating a distinct flavor and aroma." Washed rinds act as a sealer, locking in deeper flavors. They require a brine, which can be custom-made with extra ingredients, to boost to the cheese's flavor. This type of rind is typically light orange or red, with a tangy, salty taste.

"Soft-ripened cheeses," Bonilla continues, "like Brie, develop a delicate, edible rind as mold cultures grow on the surface." This is a bloomy rind, forming a soft white coating all over the cheese. It adds an earthy flavor from the edible mold, produced by intentionally spraying the outside of the cheese and increasing the humidity in the environment.

Consistency is key in cheesemaking

To make a quality product, cheese requires consistency during preparation and aging. "Cheesemakers ensure consistency across a single cheese wheel," Shannon Bonilla tells us, "through careful handling and monitoring." One part of the art of cheese making is tending to the wheel regularly. Artisans flip cheese wheels to promote balanced moisture distribution, Bonilla says, as well as even aging. Cheese wheels shouldn't be rushed. Slow and consistent heating, notes David Major, is key to cheesemaking, including the careful application of salt.

It's through the regular care of the wheel that the style of cheese is honed. Whether it's small wheels of fresh cheese or large wheels of aged cheese, treating the rounds consistently produces a top product. Beyond flipping the wheel, Bonilla says, "[Cheesemakers] can wash them frequently to develop the desired rind and flavor, and closely inspect them throughout the process." Every step in the cheesemaking process is a chance to shape the final outcome. Bonilla notes that the attention to detail and learned skill ensure the rind forms properly, resulting in the intended texture and taste.

Cheese is stamped for identification reasons

Ever notice those letters and numbers stamped on a cheese wheel's rind — the ones that make you stop and wonder if it's really safe to eat that part, even if the rind is edible? Well, they're there for a reason. These impressions, Lindsey Datz explains, are used for identification purposes. What gets stamped on a wheel depends on the cheesemaker, but it's how they mark the age and type of cheese. "For instance," she says, "our cheese is usually stamped with one number to represent the year and another one to two numbers to represent the batch."

Furthermore, Shannon Bonilla says, "The markings or stamps on cheese wheels can indicate its origin, quality and production details, allowing for traceability and quality control." Cheesemakers adhere to strict, top-notch standards, and some artisans show this off with a mark on their wheels. Plus, she adds, "Tracking numbers are essential for food safety, ensuring each wheel can be traced back to its production details."

A well-developed rind should be free from defects

With all the time and care a cheesemaker puts into crafting a wheel of cheese, the rind should develop without defects. "You can often assess the quality of cheese just by examining the outside of the wheel," Shannon Bonilla informs us, "especially with washed-rind or soft-ripened cheeses." Just using your eyes and nose to check out the appearance, texture, and smell can tell you a lot about how well the cheese is aging. "A well-developed rind," she says, "should be uniform and free from cracks or unwanted mold." David Major adds, "Wet spots, cracks, or wrinkled rinds all indicate problem cheese." Any defect in the rind can compromise the cheese inside, potentially ruining its quality.

Perhaps it goes without saying that the outside of a cheese wheel should look pretty pristine — hinting at high-quality innards. But this is just another reason why cheese is aged as a round shape — to help minimize the potential for rind defects.

There's a cheese wheel that resembles the moon

The moon may not be made of cheese as the quirky saying suggests, but there's an artisanal cheese that mimics the moon, says Shannon Bonilla — and it is aptly named Luna. This World Champion cheese from Hill Valley Dairy goes through a unique production, blending Alpine and Gouda styles into a tasty mishmash. It's cave-aged, where it develops a natural rind. "The aging process and flavor development are exceptional," Bonilla states, "making it an innovative and standout cheese." Luna features a nutty, tangy bite with a slight crunch and an earthy tone from its edible rind.

The moon and cheese have been linked for generations, tied to countless versions of that old proverb, and other cheesemakers are onboard with crafting cheeses that capture the moon. Italy's Caciocavallo takes on a different spin — aged as hanging rounds that look like little moons. Its color is also similar to the moon. And of course, the original Swiss cheese, Emmentaler, with its cratered, moon-like look most people instantly recognize as Swiss.

Runaway mold can make cheese look like a mushroom

Mold can play a critical role in aging some cheeses, but mold inside the cheese? That's not desirable. This is the main goal of the rind — to protect the cheese. Mold that goes unchecked has the potential to ruin the cheese by seeping in through cracks and edges. Most cheesemakers, though, take their craft and passion to heart and visually inspect the wheels on a regular basis. This attention to detail helps ensure top quality at all times. But what happens if something isn't spotted? If mold is allowed to grow inside, what happens to the cheese? Is moldy cheese safe to eat?

Lindsey Datz tells us about the strangest looking cheese she's seen. "[It] was a wheel of Verano," she says, "where the mold had gotten inside the wheel." A large crevice went unnoticed during the pressing process, she explains, letting mold creep further into the cheese than usual. "When it was cut open one side was wrinkled and very dry," Datz notes, "It almost looked like a mushroom."

Cheesemaking is a craft

Cheesemaking is a craft that dates back thousands of years. While it might have started simply as an accident, cheese has since turned into a form of art where size, shape, and flavor are transformed to suit desired tastes. "The cheesemaker, a true craftsman," Shannon Bonilla says, "focuses on both flavor and the science behind it, creating something truly special." That's where artisanal cheeses shine. Crafted in small batches with simple, typically locally sourced ingredients, artisanal cheese stands out as a higher end pick over mass-produced cheese.

Crafting cheese with attention, finesse, and style means cheesemakers lean on traditional methods with the proper environment, like aging cheese wheels in caves. Take Dunbarton Blue, for instance, says Bonilla. This blue cheese from Roelli Cheese Haus, she explains, comes from milk sourced daily from the same local farm. It's also aged in the cheesemaker's caves located right behind their facility.